Woodworking mill warehouse management

The system is designed for address keeping of sawn timber packages and controlling forklift trucks operation when moving, placing and shipping sawn timber packages at warehouses.

Opti-Storage works at all main production stages of a woodworking mill: delivery of sawntimbers from green sorting lines, operation of equipment at the drying complex, placement of packages with finished goods to warehouses, shipment of finished goods.

Opti-Storage description

Main principles

The system connects to controllers/databases of the equipment producing lumber packages (green and dry lumber sorting lines). At those stages of production, which are not automated, the system provides separate workplaces with the necessary user interface.

Forklifts, using Opti-Storage, have tablets with GPS / Glonass receivers, which communicate with the Opti-Storage server via 3G / LTE or Wi-Fi network.

During operation, Opti-Storage receives information about the production of a lumber package or about the need to relocate it (to a warehouse or to a drying kiln). Having received this information, the system:

- optimally places this package in a warehouse; or, in the relocation mode, selects the optimal package with desired properties,

- transfers all necessary information to the forklift tablet as a task for the driver (the number and properties of the package, current location, and destination)

The driver, having received from Opti-Storage the task to relocate a package, arrives at the current package location, confirms by the touch of a button on the tablet screen that the package has been taken to the forklift; relocates the package to a new destination, and confirms the operation by the touch of a button.

Decision-making logic

When moving packages to the warehouse, Opti-Storage minimizes pick-and-place operations:

- when placing packages of finished products, the system will co-locate packages with similar properties or packages for shipment to one customer in one transport;

- when placing packages with semi-finished products, the system minimizes pick-and-place operations between production areas (drying, dry sorting)

- when assigning several operations to a driver, Opti-Storage will issue tasks based on priorities;

- when several forklifts operate in one area, tasks will be assigned taking into account the current position of each machine and previously assigned operations;

- The system will monitor the execution of tasks, warn about errors and about performing unspecified work, deviations from the route, keep a log of violations and downtime.

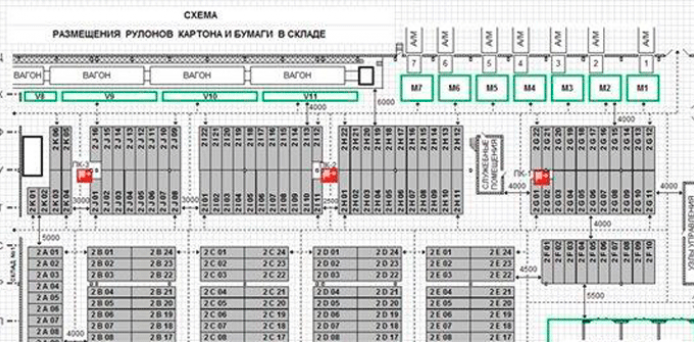

Pulp-and-paper mill warehouse management

The warehouse should be arranged into separate, numbered storage areas (cells) with own unique code. Cells are universal for storing any produced item. A cell is characterized by the number of storage places and height. It is possible to place 2 or more units (on top of each other) per storage place in a cell. The number of units in a column is limited by the cell height, or by rules. Thus, each stored unit in a cell has 2 coordinates: the column number and level (storey). All columns in the cell are lined up so that only the last roll put into it can be removed from the cell. A new item can only be placed on the edge, i.e. a cell is a stack ("first in, first out").

System functions

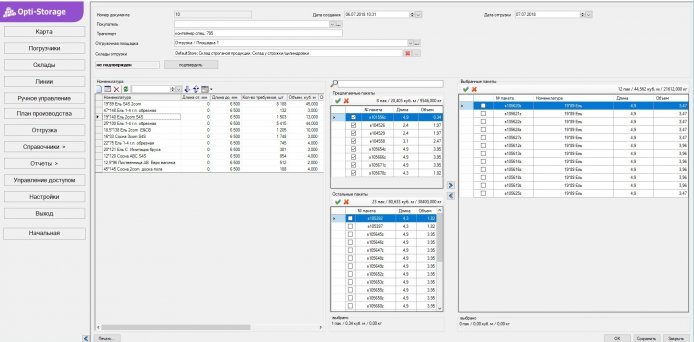

The task of optimal placement of items in stock

The main strategy of product placement is aimed at reducing the time of subsequent shipment operations. When solving this task, the following parameters are taken into account:

- Current shipments (items that must be moved to the shipping area for loading into vehicles that are currently being loaded or will arrive in the coming hours)

- Planned shipments (items, the shipment of which is planned for the near future)

- Production plans (for the next hours, shift, day)

- Corporate information system (CIS) should contain all basic data about production and stock. When an item arrives at the warehouse, the CIS provides to the System the item parameters and required production and storage information.

The task of optimal shipment of items from the warehouse

The main shipping strategy is to reduce vehicle downtime in the loading area. When solving this task, the following parameters are taken into account:

- Current shipments

- Scheduled shipments

- Production plans

- The CIS provides to the System parameters of the item to be shipped, and the System returns the item number, its storage address, and the destination.

An item is removed from a cell according to the following rules

The shipped item should be in the best available position (i.e. the time to move it from current location to the shipment area should be minimal, taking into account the pick-and-place operations of other items)

After the completion of the shipment operation, the warehouse state (cell occupation by items) should not deteriorate

The shipped item can have multiple properties, stored in the CIS, based on the customer needs and production capacity.

The task of optimizing the storage of items

The main optimization strategy is aimed at reducing the time to complete subsequent shipment operations.

During initial warehouse optimization, all receiving and shipment operations are stopped to complete rearrangement operations.

Optimization of warehouse space, reduction of overstocking

Optimization of warehouse space, reduction of overstocking  Reduction of unproductive operations (e.g., related to unnecessary relocation of pallets, rolls)

Reduction of unproductive operations (e.g., related to unnecessary relocation of pallets, rolls)  Increased staff productivity and efficiency of equipment used in servicing the warehouse and shipping

Increased staff productivity and efficiency of equipment used in servicing the warehouse and shipping  Reliability of information on the status of warehouses, minimization of human factor errors

Reliability of information on the status of warehouses, minimization of human factor errors  Transparency of finished goods placement and identification, "online" inventorying without interfering the warehouse operation

Transparency of finished goods placement and identification, "online" inventorying without interfering the warehouse operation  Decreased volume of finished goods rejected due to long storage and excessive movement

Decreased volume of finished goods rejected due to long storage and excessive movement