The system takes into account the following production features and constraints:

- The ability to make the best plywood bonding schemes according to various criteria (yield by volume or by grades, marginality, revenue, etc.);

- Constraints on veneer formats depending on the format of plywood;

- Constraints on permissible types of transverse and longitudinal veneer, depending on the grade of plywood;

- Constraints on allowable species of veneer, depending on the plywood species and possibility to make plywood from various species of veneer;

- Polishing and lamination of plywood;

- Constraints on plywood bonding depending on its thickness: the number of layers, the thickness of the jacket and internal layers, the types of internal layers;

- Ability to set several bonding schemes for one plywood thickness differing in veneer thickness and other;

- Accounting for veneer parameters: jacket grade, type, format, thickness, species, humidity;

- Accounting for veneer formats for raw and dry veneer;

- Accounting for plywood parameters: format, thickness, grade, species, lamination, tongue and groove, water resistance;

- Constraints on plywood, produced outside of ordered volumes;

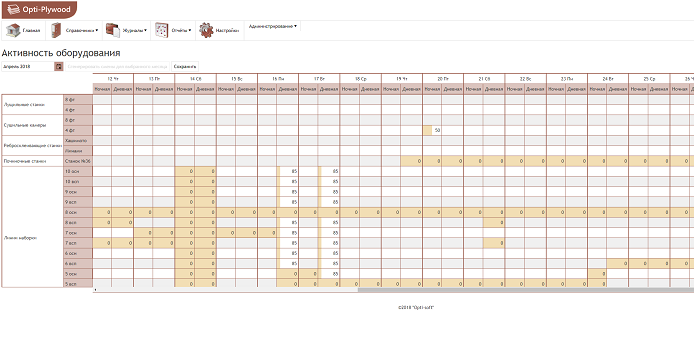

- Ability to set shifts calendar and equipment activity;

- Orders priorities;

- Limiting the permissible formats of veneer for peeling machines and accounting for production capacity;

- Accounting for veneer grades distribution after peeling machines, depending on the species and veneer type;

- Limiting the permissible formats of veneer for drying kilns, taking into account raw material consumption coefficients for peeling chambers;

- Accounting for veneer grades distribution after drying kilns, depending on the warehouse, the type and humidity of the veneer;

- Accounting for the capacity of repairing machines and raw material consumption ratios

- Accounting for veneer grades distribution after repairing machines;

- Limiting permissible thicknesses and formats of veneer for edge-gluing machines, the ability to specify operations for changing the type of raw material for edge-gluing machines;

- Constraints on presses and bonding lines according to formats, grades and thickness of plywood produced;

- Accounting for the presses performance and bonding lines, depending on the plywood thickness;

- Accounting for plywood grades distribution after presses (grade "drops");

- Constraints on permissible formats for formatting machines;

- Accounting for formatting machines capacity, depending on the plywood format;

- Accounting for laminating machines capacity

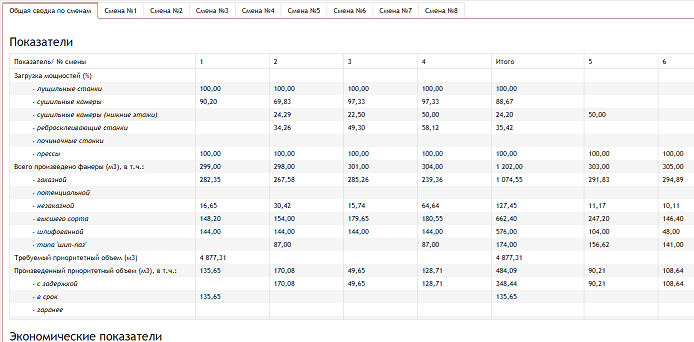

The system takes into account the following requirements, parameters and constraints on shifts:

- The minimum and maximum average thickness of the produced plywood;

- The minimum and maximum volumes of products for grinding and thorn and groove;

- Minimum and maximum production volumes by grades, formats and thickness of plywood;

- Fixing production volumes for a given product on a certain press;

- Accounting for priority orders volumes to determine the order of their fulfillment by volumes;

- Accounting for equipment work and repair schedule;

- Limiting the “complexity” of creating a production program for a shift for equipment;

- Ability to create patterns of shifts

The system ensures that requirements and technological features are taken into account for scheduling:

- Accounting for shipment schedule of finished goods, and priority of production orders;

- Schedule of equipment operation - the possibility to set requirements and technological features for shifts, accounting for planned repair works;

- Availability of veneer, as well as expected deliveries;

- Minimum and maximum veneer storage times

Increased profitability of production, total yield and/or yield of higher grades

Increased profitability of production, total yield and/or yield of higher grades Reduction of time spent by personnel on planning and control procedures due to automation of these processes

Reduction of time spent by personnel on planning and control procedures due to automation of these processes Increased efficiency of obtaining information on key performance indicators of the mill as a whole, and individual orders

Increased efficiency of obtaining information on key performance indicators of the mill as a whole, and individual orders Reduction of in-process inventory at all levels by end-to-end planning and optimization throughout the entire production chain

Reduction of in-process inventory at all levels by end-to-end planning and optimization throughout the entire production chain Reduction of production orders execution time due to reduced equipment downtimes and tighter schedule

Reduction of production orders execution time due to reduced equipment downtimes and tighter schedule